Hitesh Gandhi

+919879091953

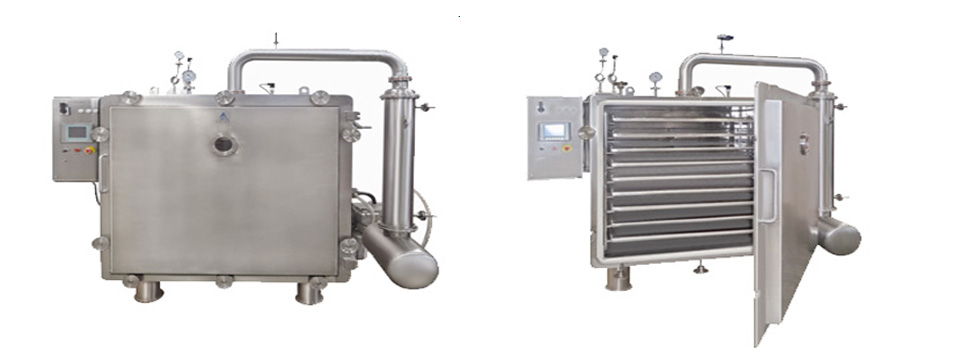

Industrial Vacuum Tray Dryer is best suited for drying thermally sensitive materials, which are easily resolved, polymerized or deteriorated under higher temperature. Before these processes sterilization can be performed, during which no other matter is allowed to come in contact with the product. There are Static vacuum dryers that completely eliminate the configuration damage of the drying materials. Hence, our VTD range is broadly used in pharmaceutical, chemicals and foodstuff sectors, among others.

Features of Vacuum Tray Dryer GMP-based Model:

Main Body/Vacuum chamber SS316 with heavy duty SS316 flange and Stiffeners

Door SS 316 (hemisphere shape) with heavy duty SS316 flange

Shelves Hollow Type pads SS316 with flow Baffles

Condenser (Shell & tube) and Receiver in SS 304 with Isolation valve and Flow Glass in between to monitor condensation

Trays (without back folding) in SS316 rounded corners and edges

Explosion Vent/Rupture Disc on vacuum chamber

Digital Temperature Controller (FLP) with solenoid controlled Pneumatic operated valve at Hot Water inlet

Provision for Validation Port on Body

Digital Temp Indicator (FLP) at H.W. inlet & outlet

Dial type Vacuum gauge and Digital Temp., Indicator (FLP) in Vapor line

Pressure release valve in Steam line

View Glass/Light glass provided on vacuum chamber Door, Body and Receiver

Silicon transparent gasket for door

Nitrogen purging valve provided on Vacuum chamber

Vacuum break valve provided on vacuum chamber

Drain valve for Vacuum chamber and Receiver

Temperature Accuracy: _+ 2 to 30C

Finish: Internal 320 Grit Mirror Polish and Outer 180 Grit Mat Finish

| No. Of Trays | 3 | 6 | 12 | 24 | 36 | 48 | 96 |

| Capacity in Kg | 3-5 | 12-18 | 25-35 | 50-75 | 75-100 | 100-150 | 200-300 |

| Tray volume in Ltrs /Capacity in Kg | 5/1-1.5 | 10 /2-3 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 |

| Tray size : L W H in mm | 406x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 |

| No. of Heating Shelfs | 4 | 7 | 7 | 9 | 13 | 17 | 17 |

| Shelf size in mm | 430x430 | 430 X835 | 835x835 | 835x1259 | 835x1250 | 835x1250 | 1250x1650 |

| Distance between shelves in mm | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Trays on each self | 1 | 1 | 2 | 3 | 3 | 3 | 6 |

| Condenser | 0.2m2 | 0.5 m2 | 0.75m2 | 1m2 | 1.5m2 | 2m2 | 3m2 |

| Receiver | 10Ltrs | 25 Ltrs | 50 Ltrs | 75 Ltrs | 100 Ltrs | 150 Ltrs | 250 Ltrs |

| H.W. Distribution Pipes | 1½" | 1½" | 1½" | 1½" | 1½" | 1½" | 2" |

| Door Gasket (Silicon) | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ |

| No. of Door Bolts (Φ40) | 4 | 6 | 8 | 10 | 12 | 12 | 14 |

| Design Temperature : 1500C, TESTING : The vacuum dryer shelves arehydro-tested 5 Kg/Cm2 in Assembled condition. The vacuum chamber is tested for full vacuum. | |||||||